- Counting Machines

- REA Verifier

- X-Rite

- TMI

- Printing and Packaging

- Chemical Testing Analysis

- Tisch/AADCO

Mobile:13926416086

Fax:020-32032628

Products

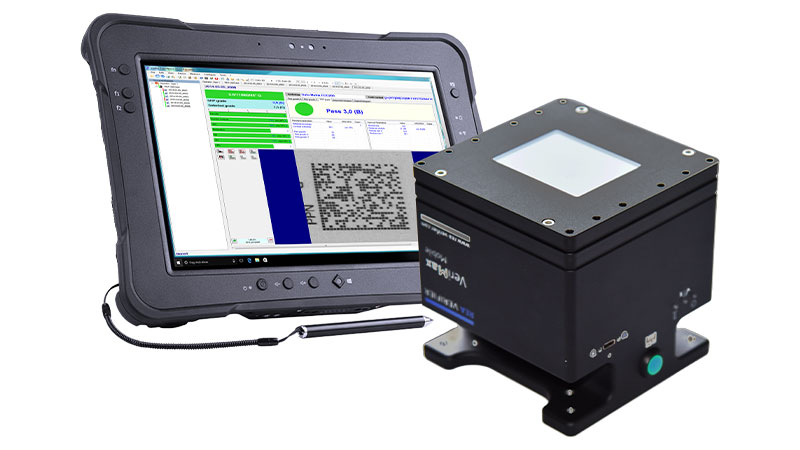

Verimax mobile Verifier

| Model: | Verimax mobile |

| Price: | 面议 |

Flexible code verification - avoid errors and costs The REA VeriMax Mobile is configured for mobile use in production, laboratory, incoming goods and quality assurance.

The offline verification device is suitable for measurements of samples and comes with its own tablet PC.

It verifies the quality of 1D/2D codes to ensure that regulatory quality specifications as well as user specifications

are met.

By ensuring high code quality and eliminating incorrect code content, the REA VeriMax Mobile can significantly

help reduce costs. This is because unreadable barcodes force manual entries, which increase the risk of errors and

delay the entire operational process. With REA VeriMax Mobile, you can quickly find out

how to improve code reading rates. The detailed measurement results serve as a basis

for optimizing the print quality of codes as well as for assessing scanning performance.

Routine code inspection enables corrective action to be taken immediately to boost automation and maintain

competitiveness. Due to its size of 12 cm and the ergonomic handle, the

verifier can be used flexibly. Depending on the verification situation, there is the option of mounting the tablet

PC directly on the cube using a universal holder or connecting it to an existing Windows PC/tablet with

USB-3 interface.

Areas of application

Offline device

Mobile use as stand-alone device or with PC

Verification of 1D/2D code quality according to

international standards, GS1 and other specifications

Ensuring high first read rates

Capture and recording of all production relevant

data in relation to production batches

Features

Code verification by a CMOS camera system

Measurement of optical codes with defined angles, distances and illuminations (ISO standard-compliant)

Darkened measuring chamber to avoid ambient light influences

Verification according to ISO/IEC 15415 for printed matrix codes and ISO/IEC 15416 for printed barcodes

Verification according to ISO/IEC 29158 (formerly AIM DPM guideline 2006)

Verification in compliance with GS1specifications

Verification of optional parameters to optimize the print process

ISO/IEC 15418 / ANS MH10.8.2 Data structure analysis

If required, adapted cover plates can be constructed

Advantages

Specific code selection and configuration for all industries

Can be used as stand-alone device or optionally with connection to 8.4“ or 10.1“ touchscreenoptimized tablet PC

User detaches from stationary workstation and can speed up verification processes

Settings for user-defined profiles for easy operation and faster selection

Device, interface and evaluation software supplied as a package

High measurement accuracy and measurement repeatability due to optimized design

Monitoring of all marking requirements, regardless of the qualification of the personnel used

Multilingual user interface and reports

Code Types

Matrix Codes (2D)

ISO/IEC 16022 Data Matrix, ISO/IEC 18004 QR-Code,

ISO/IEC 24778 Aztec Code, ISO/IEC 20830 Han Xin

Code, AIM ISS DotCode, ISO/IEC 15438 PDF417,

ISO/IEC 24728 MicroPDF417

Barcodes (1D)

ISO/IEC 24723 Composite Code, ISO/IEC 15420 EAN/

UPC (EAN-13, EAN-A, UPC-A, UPC-E and Add-On),

ISO/IEC 15417 Code 128, ISO/IEC 16388 Code 39

(with PZN and Code 32), ISO/IEC 16390 interleaved

2 of 5 including ITF-14, ISO/IEC 24724 GS1 DataBar

Optional Codes

2/5 3 Bars, 2/5 5 Bars, 2/5 IATA, 2/5 Baggage, 2/5

DHL Express (Frachtpost-Code), Code39 Full ASCII,

Code93, MSI, Plessey, Codabar Monarch (18), LAETUS

Pharmacode, LAETUS Mini Pharma Code, Russian

Crypto Code, China Drug Supervision Code, Japan CVS

payment Code, UPU-S10 Postal Codes, DPD Parcel Service

Data structures and code properties

GS1 data structures: GS1 DataMatrix, GS1 QR-Code,

GS1-128, GS1 Databar, GS1 Composite Code), Crypto

Code (GS1 General Specifications)

ISO data structures: ISO/IEC 15418 / ANSI MH10.8.2,

ISO/IEC 15459 (part 1 to 8), ISO/IEC 15434 used by

Issuing agencies and associations: AIAG, Odette, VDA,

EDIFICE, HIBC, DOD, UPU, JEISA, JEITA, IFA …)

ISO 28219, ISO 22742, ISO 15394

EFPIA and PPN support for pharmaceutical industry (delegated Act EU 2016/161 and UDI/MDR 2017/745, 2017/746, US DSCSA, Turkey and more, US GUDID alignment (UDI)

DOD MilStd 130 IUID support, AIT (German Armed Forces)

Check digit control settings

Size control settings

Customizable date verification

Optional database (item number verification)

Evaluation

ISO/IEC 15416 for barcodes, ISO/IEC 15415 for 2D Codes

ISO/IEC 29158 and SAE AS 9132 for DPM

GB/T 14258 (China barcode), ANSI X3.182